Aden M&E Pte. Ltd. will provide the following Fire Rated Ceiling, Partition, Curtain wall, Smoke Barrier, External Cladding Systems with Promatect-H / Durasteel / Promatect-S / Promina-60 / Promatect-L500 boards

These are normally non-loadbearing and, depending on the type of construction, are used to provide protection from fire attack from below and/or above. Ceiling panels are fixed into a steel framing system spanning and supported between two walls. Self-supporting membrane ceilings should normally be tested or assessed in accordance with BS476: Part 22 and/or AS1530: Part 4 to satisfy the failure criteria of integrity and insulation. These ceiling systems allow for the protection to or from services contained within the ceiling void. They will also provide protection to steel beams that are required to meet the criteria of BS476: Part 23 where exposure to fire is from below / above.

Advantages:• Assembling of a single layer of PROMATECT®-S board, 9.5mm thick, screwed onto both sides of galvanised steel studs

along with a double layer of cover strips, two layer of mineral wool cavity infill in between the partition wall, for a total system thickness of 157mm.

• PROMATECT®-H is a non combustible matrix engineered mineral board reinforced with selected fibres and fillers. It does not contain formaldehyde. PROMATECT®-H is off-white in colour and has a smooth finish on one face with a sanded reverse face. The board can be left undecorated or easily finished with paints, wallpapers or tiles. PROMATECT®-H is resistant to the effects of moisture and will not physically deteriorate when used in damp or humid conditions. Whilst its performance characteristics are not degraded by age or moisture, For application in areas subject to continual damp or high temperatures, please consult Promat.

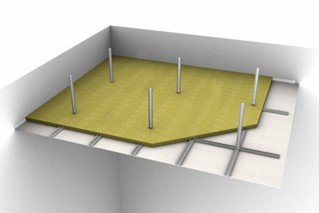

• Assembling of a two layer of PROMATECT®-L500 board, 2 x 30mm thick stagger joints, screw-fixed onto perimeter steel angle frame.

• Assembling of a single layer of DURASTEEL® board, 9.5mm thick, screwed onto both sides of galvanised steel studs along with a cover strip, with two layer of mineral wool cavity infill in between the partition wall, for a total system thickness of 118mm.

•Up to 2 Hr Rating

• Light Weight

• Easy to install

• Neat and clean

• Application – Use between floor slab and external cladding

• 2 Hr Rating

• Single layer board

• Can be use as sign direction

• Application – Atrium, large ceiling void

• Up to 4 Hr Rating

• Single layer board

• Unlimited Height & Length

• Installation from one side

• Application – FR Hording, Industrial building external wall